GHT technology solves waste disposal problems

Green Hydrogen Technologie’s production process relies on climate-friendly hydrogen production from plastic waste, wood waste and sewage sludge.

Plastic waste

Today the potential that lies in non-recyclable plastics is not fully used. Germany alone produces more than 3.8 million tons of non-recyclable plastics per year (source: Plastic Atlas, Bund für Umwelt und Naturschutz Deutschland, 2019). These residual materials are incinerated, landfilled or even disposed of in our oceans. In the GHT process, valuable synthesis gas is created from plastic waste and thus provides an economic and ecological benefit.

Wood waste

Despite well-developed recycling systems, a large proportion of wood waste cannot be recycled. In Germany, this amounts to 11 million tons per year (source: Technology for Wood and Natural Fiber-Based Materials. Research project of the Fraunhofer Institute. Data: Federal Statistical Office, 2020). In the GHT process, valuable synthesis gas is produced from wood waste.

Sewage sludge

In Germany alone nearly 1.9 million tons of sewage sludge are produced annually (source: Eurostat Data, 2020). Sewage sludge contains valuable phosphate. From 2029, EU law requires that phosphate be removed from sewage sludge before it is disposed in landfills. So far no economical process exists. Extraction is complex and expensive.

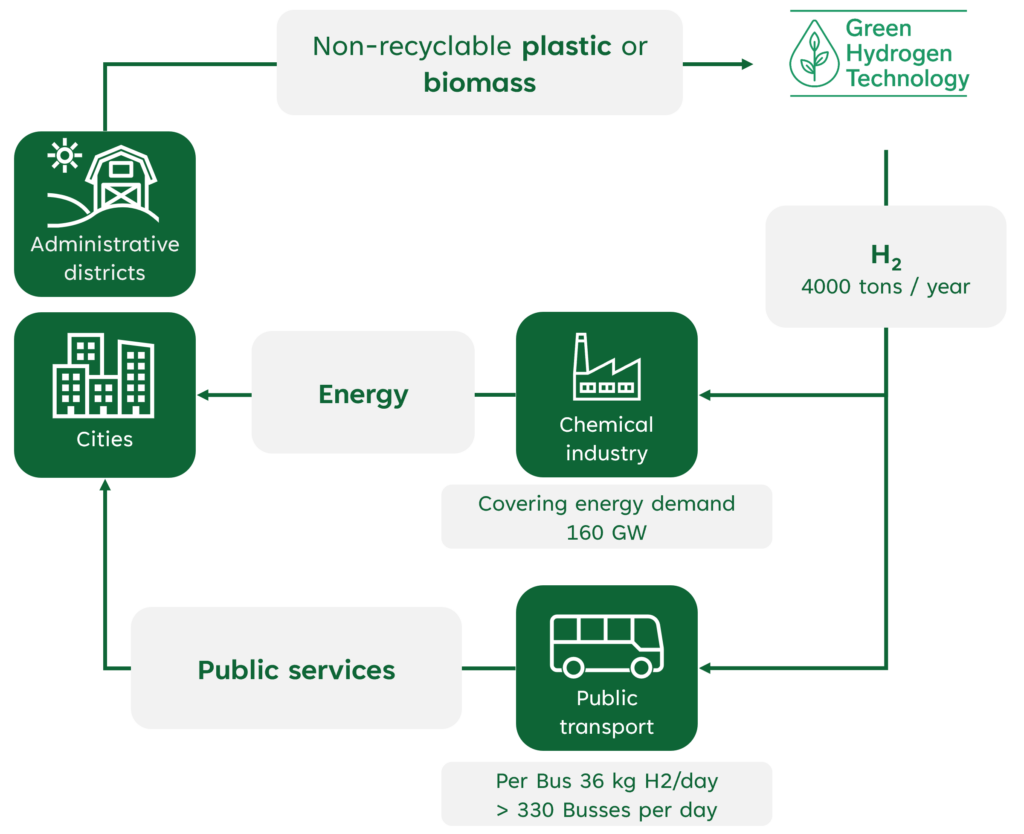

APPLICATION MARKETS

Tailored to local needs and conditions

GHT technology serves a wide range of applications where the availability of economically produced climate-neutral hydrogen on an industrial scale is important. It is suitable for operators in industry, the energy sector and the municipal sector, among other areas.